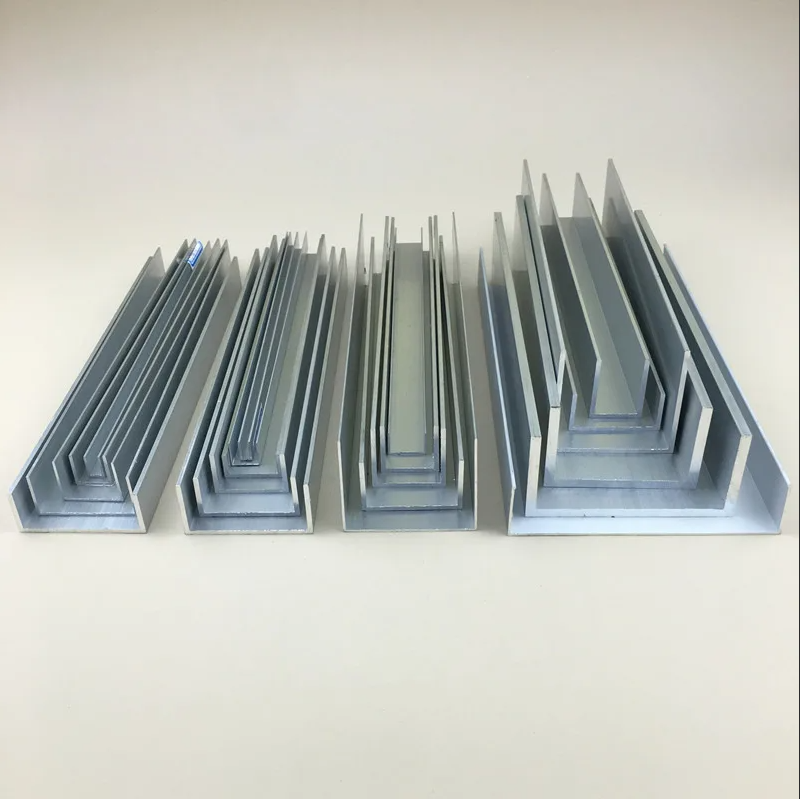

High quality A 36 Z-shape steel

High section: The section height of Z steel is mostly between 120-350mm. Small thickness: The thickness of Z steel is generally between 1.6-3.0mm. Processing materials: Z-shaped steel processing materials are hot rolled (spray paint), galvanized. Application: Z-shaped steel is usually used in large steel structure plants, and can also be used in other building structures.

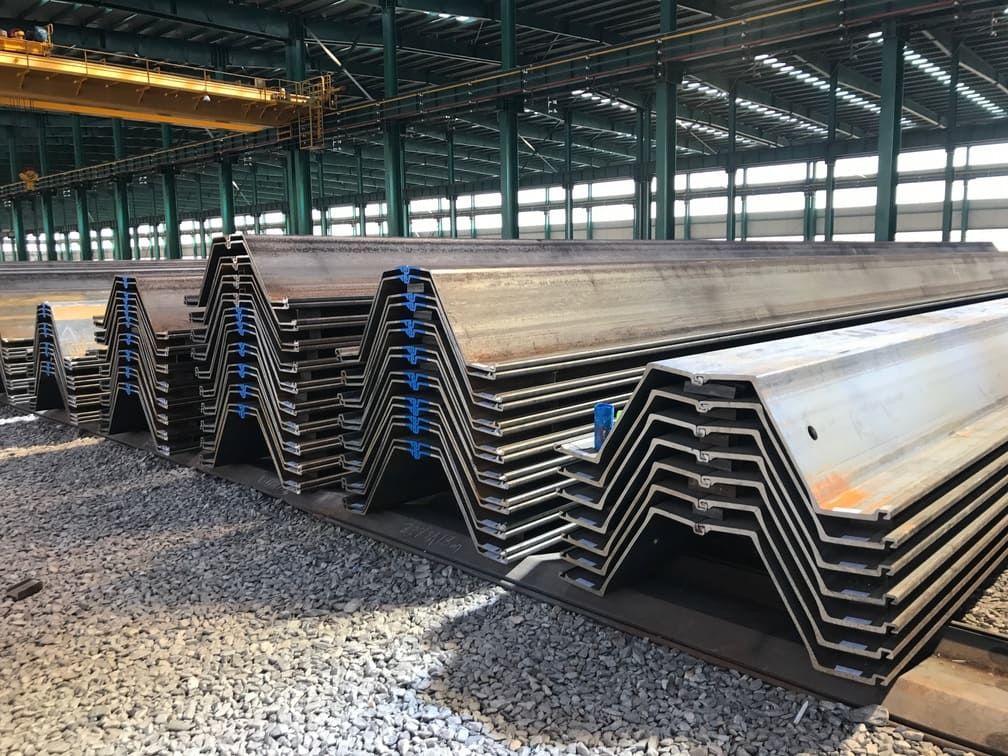

China factory high quality A 36 steel sheet pile

1,The pile length is easy to adjust. The length of steel sheet piles can be lengthened or adjusted according to needs. 2, connector connection is very simple. It can be welded by electric welding, simple operation, high strength and safe use. 3, the amount of abandoned soil is small, and the impact on adjacent buildings (structures) is small. Due to the opening at the lower end of the pile, soil will be squeezed into the pile pipe when the pile is driven. Compared with the actual pile, the amount of soil squeezing is greatly reduced, the disturbance to the surrounding foundation is small, the soil uplift is avoided, and the influence of the vertical and horizontal displacement of the pile top is greatly reduced. 4, high carrying capacity. The steel has high strength, can be effectively driven into the hard soil, the pile body is not easy to damage, and can obtain a larger single pile bearing capacity. 5, reliable engineering quality, fast construction speed. 6, light weight, good rigidity, loading and unloading, transportation, stacking convenient, not easy to damage.

Round steel is mainly made of carbon steel, alloy steel and tool steel. Among them, carbon steel round steel refers to steel with carbon content within the range of 0.20% to 0.55%. Carbon steel round steel is an economical and practical structural material with good weldability, plasticity and machinability. Alloy steel round steel refers to the steel with a certain amount of alloying elements (chromium, manganese, cobalt, boron, molybdenum, vanadium, etc.), which can obtain higher strength, hardness, corrosion resistance and wear resistance. Tool steel Round steel is a kind of high-speed tool steel material, which has the advantages of high hardness, high red hardness and wear resistance. Therefore, the material characteristics of round steel are very different from the scope of application.

Round steel has excellent toughness and machinability. Because of its cylindrical shape, round steel is easier to cut, weld and process into various shapes, such as round rods, shafts, supports and tools. This makes round steel widely used in construction, machinery manufacturing, aerospace and other industries. Secondly, round steel has good strength and wear resistance. Round steel is generally made of high-strength steel. In various occasions with high strength requirements, such as Bridges, stairs, construction supports, etc., round steel can play a stabilizing and supporting role. At the same time, round steel can also withstand greater impact force and friction, so that it is widely used in the field of mechanical equipment manufacturing, automobile manufacturing and other wear-resistant materials. Third, round steel has good plasticity and weldability. Round steel can be cold or hot worked into various shapes, and it can be joined with other materials through processes such as welding and heat treatment. This makes round steel ideal for the manufacture of structural parts, pipes and connectors. In addition, round steel also has corrosion resistance and high temperature resistance. Many round steel types are corrosion-resistant, rust-resistant or made of stainless steel, enabling them to be used in wet, acidic or alkaline environments. At the same time, some special materials of round steel, such as high chromium and high nickel alloy, can maintain its strength and stability in a high temperature environment, is widely used in aerospace, nuclear industry and other fields.

High structural strength A36 H-shaped steel

1, the structural strength is high compared with I-steel, the section modulus is large, and the metal can be saved by 10-15% at the same time under the same bearing conditions. 2. Flexible and rich design style In the case of the same beam height, the opening of the steel structure is 50% larger than the opening of the concrete structure, so that the building layout is more flexible. 3. The structural weight is light compared with the concrete structure, and the reduction of the structural weight reduces the internal force of the structural design, which can make the building structure foundation treatment requirements low, the construction is simple and the cost is reduced. 4. High structural stability. The steel structure based on hot-rolled H-shaped steel has scientific and reasonable structure, good plasticity and flexibility, and high structural stability, which is suitable for building structures with large vibration and impact loads and strong resistance to natural disasters, especially for some building structures with multiple earthquakes. According to statistics, in the world's devastating earthquake disaster of magnitude 7 or more, the H-shaped steel mainly steel structure buildings have the least degree of damage. 5. Increase the effective use area of the structure Compared with the concrete structure, the section area of the steel structure column is small, which can increase the effective use area of the building, depending on the different forms of the building, can increase the effective use area of 4-6%. 6. Save labor and materials Compared with welding H-shaped steel, can significantly save labor and materials, reduce raw materials, energy and labor consumption, residues Low residual stress, good appearance and surface quality. 7. Easy mechanical processing, easy structural connection and installation, but also easy to remove and reuse. 8. Environmental protection using H-beam steel can effectively protect the environment, which is reflected in three aspects: first, compared with concrete, dry construction can be used, resulting in less noise and less dust; Second, due to the reduction of self-weight, less soil extraction for foundation construction, less damage to land resources, in addition to a large reduction in the amount of concrete, reduce the amount of rock excavation, conducive to the protection of ecological environment; Third, after the service life of the building structure expires, the structure is dismantled and produced

Chinese factories sell high quality A 36 I Beam

Application features of I-beams include: 1. Strong impact resistance and wear resistance, so its service life is long. 2. Light weight, convenient construction, help to save construction time, improve the construction period. 3. Beautiful appearance, from the appearance point of view, I-steel up and down symmetrical, in line with the public aesthetic. 4. It has the characteristics of insulation, good magnetic permeability, fire retardant, insulation and heat insulation. I-beam steel is mainly used in the steel structure of industrial and civil buildings, steel bearing brackets of industrial structures, steel piles and support structures of underground engineering, petrochemical, electric power and other industrial equipment structures, as well as long-span steel bridge components

A53 High Stiffness Channel steel

A53 Channel steel is very widely used, mainly used in construction, shipbuilding, rolling stock and Bridges and tunnels. This is because A53 channel steel has the characteristics of high tensile strength, good torque stiffness, light weight and strong anti-corrosion ability. In addition, channel steel is also widely used in solar brackets, power towers and other types of architecture, for construction, manufacturing, transportation and other industries to provide structural support.

Q195 Channel steel is a commonly used metal material, its main uses include: metal products, building decoration, nuclear power and chemical equipment and food machinery. In addition, Q195 Channel steel can also be used in the manufacture of anchor bolts, share, smoke pipe, roof board, rivets, low carbon steel wire, sheet, welded pipe, tie rod, hook, bracket and welded structure and other products.

S355 Channel steel is a kind of structural steel, its strength is high, close to the ordinary carbon steel twice, with excellent mechanical properties and corrosion resistance. Because of these characteristics, S355 channel steel is widely used in construction engineering, construction machinery and vehicles, as well as large machinery, building templates, auto parts, home appliance manufacturing and many other fields

S275JR High-quality Channel steel

S275JR Channel steel is a kind of steel with high mechanical properties, which is widely used in many fields. Specifically, S275JR channel steel can be used for: building structure, bridge construction, welding structural parts and including but not limited to heavy machinery, presses, offshore platforms, mining machinery, coal mining machinery and other mechanical equipment manufacturing In addition, S275JR channel steel is suitable for fatigue, impact and corrosion resistance applications due to its moderate high strength and toughness characteristics.

S235JR Low carbon Channel steel

S235JR Channel steel is a commonly used low-carbon structural steel, commonly used in the manufacture of building structures, Bridges, machine parts, etc. This kind of steel can be made of welded and assembled structural parts under a certain load, such as floors, corridors, cable Bridges, body frames, etc. At the same time, S235JR channel steel is also a common low-alloy channel steel, mainly used in construction, Bridges, vehicles, ships and other fields.

SS400 Channel steel is a common construction steel, with high tensile strength and yield point, can withstand large loads. After surface treatment, SS400 has good corrosion resistance, smooth surface, uniform color, not easy to rust, can resist the erosion of atmosphere, water and chemical substances, extend the service life of the building, suitable for the construction of high-rise buildings, Bridges, tunnels and other large buildings.

A36 High strength Channel steel

A36 Channel is a widely used structural steel, mainly used in the manufacture of welded and bolted metal structures in industrial and civil buildings, Bridges, and other mechanical engineering fields. This steel is popular for its high strength, good weldability and plasticity, and can be adapted to the needs of a variety of engineering structures and components. The special groove design of the A36 channel makes it particularly suitable where bearing capacity is required.

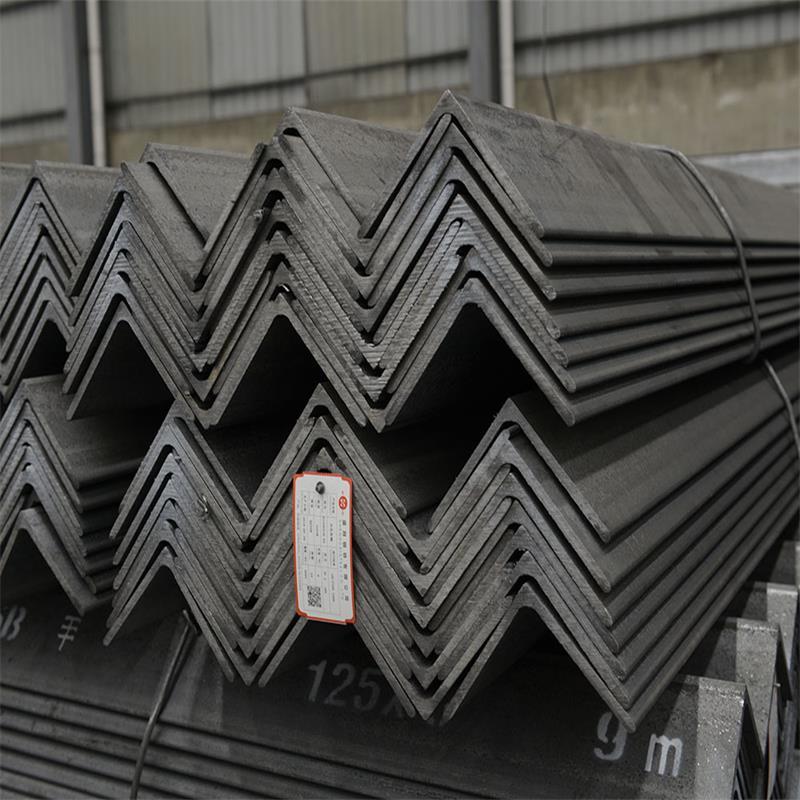

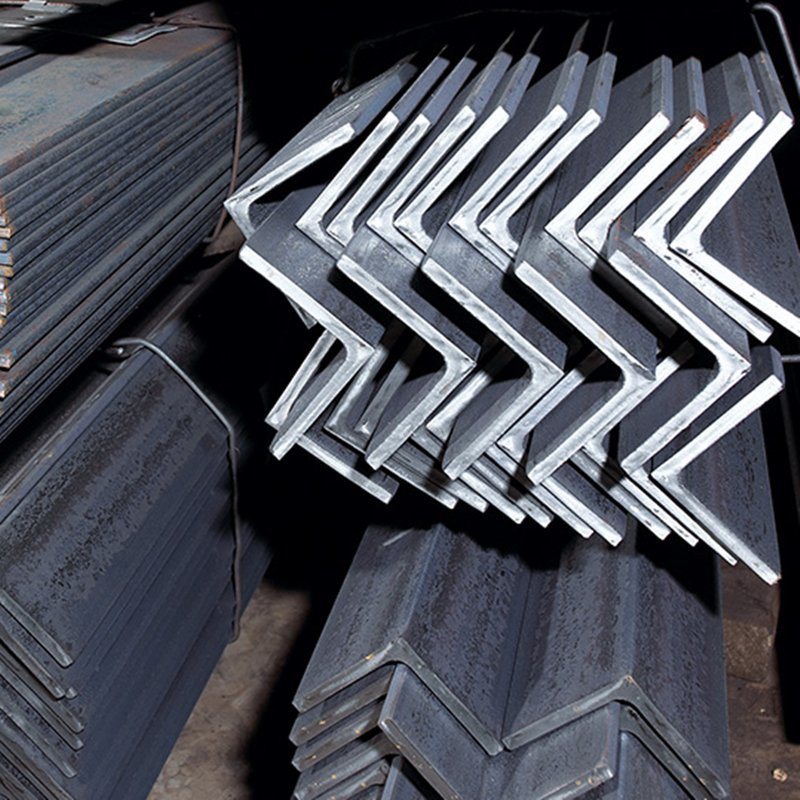

A53 Angle steel with Strong Toughness

A53 Angle steel is a common construction steel with good weldability and machinability, as well as good toughness and corrosion resistance. Therefore, A53 Angle steel is widely used in construction, Bridges, machinery manufacturing, shipbuilding, agricultural machinery and mechanical transportation, building formwork and other fields.

S275JR High strength Angle steel

S275JR Angle steel is a kind of low alloy high strength structural steel plate, with high strength, good toughness, fatigue resistance, impact resistance, corrosion resistance, welding and easy processing and other high quality properties. Therefore, S275JR Angle steel is widely used in various machinery manufacturing fields, such as mining machinery and equipment manufacturing, coal mine machinery and equipment, heavy machinery, engineering machinery, steam turbine, blade, bridge junction, mechanical parts and so on.

S235JR Angle steel is a commonly used building material with high strength, good weldability and machinability, while also having good wear and corrosion resistance. Therefore, S235JR Angle steel is widely used in building structures, machinery manufacturing, automobile manufacturing, shipbuilding, agricultural machinery, conveying machinery, Bridges, building formwork and other fields.

Low cost high quality SS400 Angle steel

SS400 Angle steel is a high-quality steel, because of its high strength, easy processing characteristics, is widely used in many industries. Specifically, the main uses of SS400 Angle steel include: construction industry, automobile manufacturing and machinery manufacturing, shipbuilding and other industrial applications such as cranes, hydraulic presses, steam turbines, heavy machinery and equipment, construction machinery and equipment.

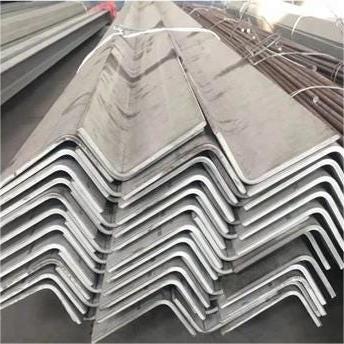

A36 Angle steel is a commonly used structural steel, mainly used to make frames, supports and other structural parts. Because of its good weldability, plasticity and toughness, A36 Angle steel is widely used in construction, ships, Bridges and other fields. In addition, A36 steel plates can also be used as basic materials for mechanical equipment and precision machinery manufacturing, as well as precision parts processing. In some cases, A36 steel can also be used as a material for welding and bolting metal structures, suitable for industrial and civil buildings as well as bridge construction.

Rebar is mainly used for: houses, Bridges, roads and other civil engineering construction, large to highways, railways, Bridges, culverts, tunnels, flood control, DAMS and other public facilities, small to the foundation of housing construction, beam, column, wall, plate, rebar is an indispensable structural material

Rebar is mainly used for: houses, Bridges, roads and other civil engineering construction, large to highways, railways, Bridges, culverts, tunnels, flood control, DAMS and other public facilities, small to the foundation of housing construction, beam, column, wall, plate, rebar is an indispensable structural material

High strength special-shaped steel Q420/Q460/Q690:Widely used in steel structure (industrial plant, wholesale market, three-dimensional warehouse, large supermarket, solar support cable tray), cars, motorcycles, railway vehicles, building doors and Windows, transportation, shelves electrical cabinets, highway guardrawers, construction steel structure, containers, steel formwork and scaffolding, shipbuilding, Bridges, transmission towers, steel sheet piles, cable tray, agricultural machinery, furniture, storage, guide Rail, keel steel, vegetable greenhouses, pipeline support, municipal construction and other fields

Q690 High strength Channel steel

Q690 low alloy high strength Channel steel is mainly used in building structure, curtain wall engineering, machinery and equipment and vehicle manufacturing. In use, it is required to have better welding, riveting performance and comprehensive mechanical properties. The raw material billet for channel steel production is carbon junction steel or low alloy steel billet with carbon content not exceeding 0.25%. The finished channel steel is delivered by hot working, normalizing or hot rolling. Class C and D can be operated in low temperature environment with high safety factor and wide application range

Q690 High strength C-shaped steel

Q690 low alloy high strength C section steel its strength, toughness, plasticity, corrosion resistance and weather resistance are stronger than the general carbon material, generally used for higher stress requirements, or higher plastic requirements, or relatively special environment work, such as low temperature, high corrosion environment. With the advantages of adjustable size and high compressive strength, it is widely used in automobile, railway vehicle, building doors and Windows, transportation, shelves, electrical cabinets, highway guardrawers, construction steel structure, containers, steel formwork scaffolding, solar support shipbuilding, Bridges, transmission towers, steel sheet piles, cable tray, agricultural machinery, furniture, storage, guide rail, keel steel, vegetable greenhouses, pipeline support , municipal construction and other fields. Q460C/Q460D can be used in buildings below -20 degrees Celsius all year round, with high safety factor and wide application range

Q235 Z-shaped steel sheet pile

Advantages: – Extremely competitive section-modulus-to-mass ratio. – Increased inertia for reduced deflection. – Large width, resulting in good installation performance. – Good corrosion resistance, the steel being thickest at the critical corrosion points. Class C and class D can be operated under low temperature transition, with high safety factor and wide use range